Vapor Control Equipment

Steel Vapor Scrubber Systems

Complete line of steel vapor scrubber units

Poly Vapor Scrubbing Systems

Wide array of poly vapor scrubber units

Carbon Filtration Equipment

Unique line of carbon adsorption units

Eliminator Series Vapor Scrubber Systems

New approach to scrubbing hydrocarbons

Vacuum Truck Scrubber Systems

Vacuum truck & air-mover solutions

Air Moving Equipment

Blowers and Air Moving Equipment

Vapor Scrubber System Rentals

Skid & trailer-mounted vapor scrubbers

Carbon Vessel Rentals

Wide range of carbon vessels for rent

Blower Rentals and Sales

Poly & metal pressure blowers

Vapor Scrubber Chemicals

Chemical medias designed for wet scrubbers

Carbon Filtration Medias

Various specialized carbon medias

H2S & Mercaptan Odor Control Chemicals

Neutralizing agents for sulfur products

Hydrocarbon Degassing Chemicals

Degassing agents for hydrocarbons

Odor Control Chemicals

Deodorants and odor neutralizers

Industrial Strength Cleaning Chemicals

Cleaning agents for industrial applications

Specialty Chemicals

Specialty products and chemicals

Engineering, Design & Custom Fabrication

Professional services available

Supplies & Equipment

Duct hoses, flame arrestors & more

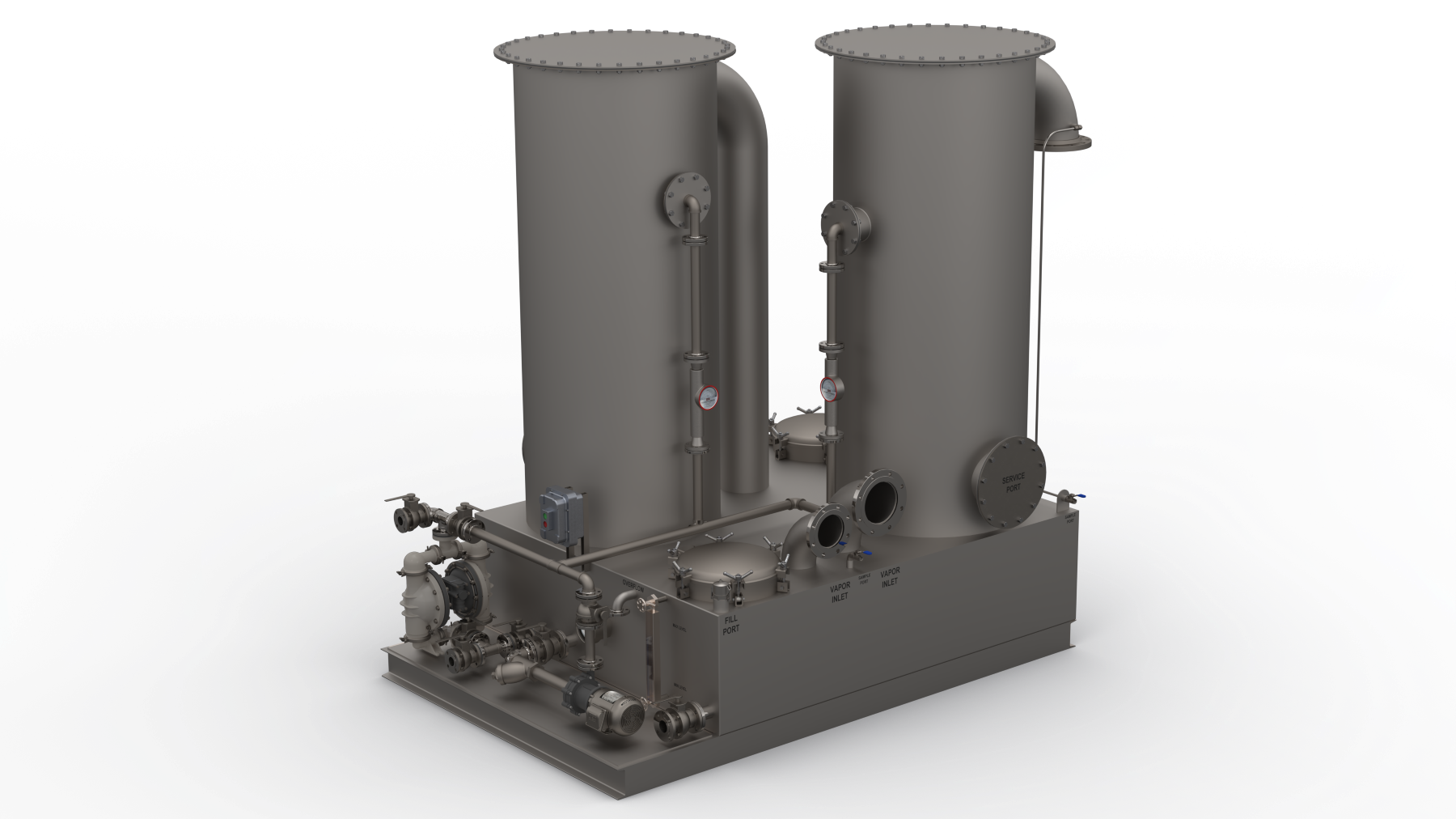

SST-20 Vapor Scrubber

Dual column stainless steel scrubber for vapor flows up to 750 CFM. Unit has twin 20" columns and is skid mounted. This unit comes equipped with a magnetic-drive pump (primary) and an air diaphragm pump (backup). Large 20" clean-out ports make maintenance on the reservoir quick and easy. This unit is available for sale and also available in our rental fleet.

SST-40 Vapor Scrubber

The SST-40 Vapor Scrubber unit is a skid-mounted stainless steel, twin-column wet scrubber designed for vapor flows up to 3000 CFM. Removal efficiencies as high as 99%+ in this scrubber unit alone! Unit comes with main electric re-circulation pump as well as a backup pump (AOD or Electric). This unit is great for scrubbing a large variety of vapors including hydrocarbons, amines, H2S, ammonia, and many more. This unit may be paired with carbon beds for polishing as well as a blower to aid in flow through the unit.

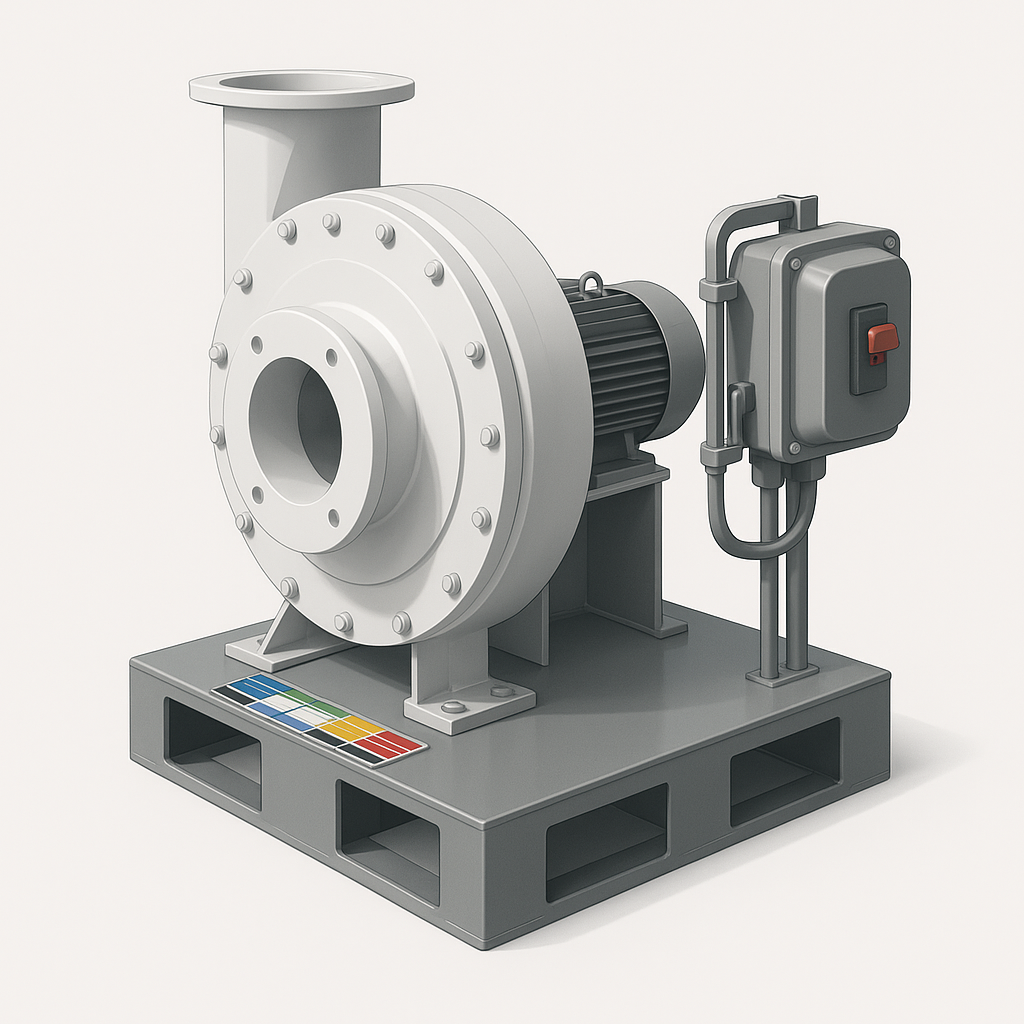

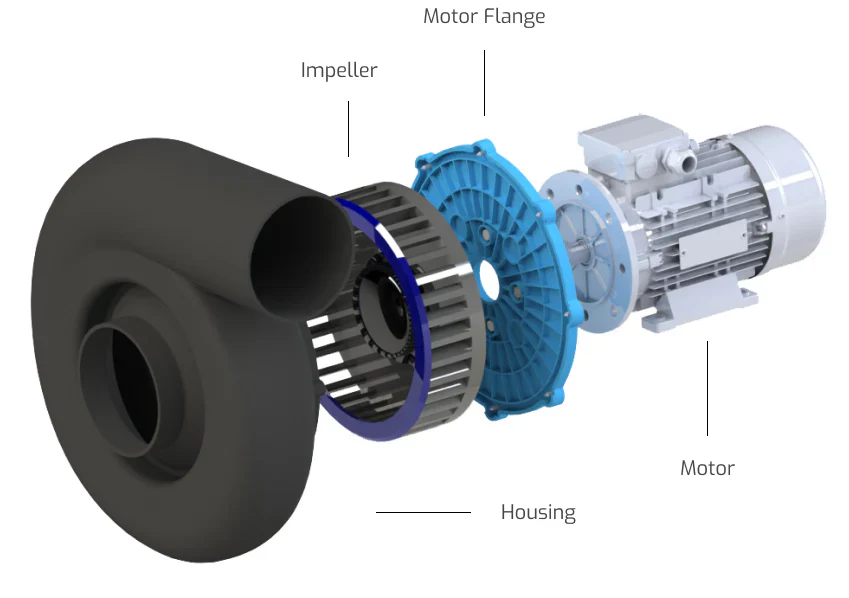

FRP1200 Poly Blower

The FRP1200 centrifugal blower is an all FRP blower rated for 1200 CFM @ 10” of water. This unit is excellent for corrosive applications such as acids and other compounds which may corrode steel materials. This unit is driven by a VFD (variable frequency drive) which makes controlling airflow simple and easy.

FRP4500 Poly Blower

The FRP4500 centrifugal blower is an all FRP blower rated for 4500 CFM @ 8” of water. This unit is excellent for corrosive applications such as acids and other compounds which may corrode steel materials. This unit is driven by a VFD (variable frequency drive) which makes controlling airflow simple and easy.

SST40-N2K System

The SST40-N2K is a trailer-mounted system comprised of a dual stainless steel packed-bed liquid scrubber (SST-40) followed by a 2000# carbon polisher and a 1500 CFM blower. Excellent for remote jobs and projects. Applications include tank cleaning, vessel and line cleaning, tank degassing and more. Overall system efficiency as high as 99.999%. Available for sale or rent. Skid mounted versions available.

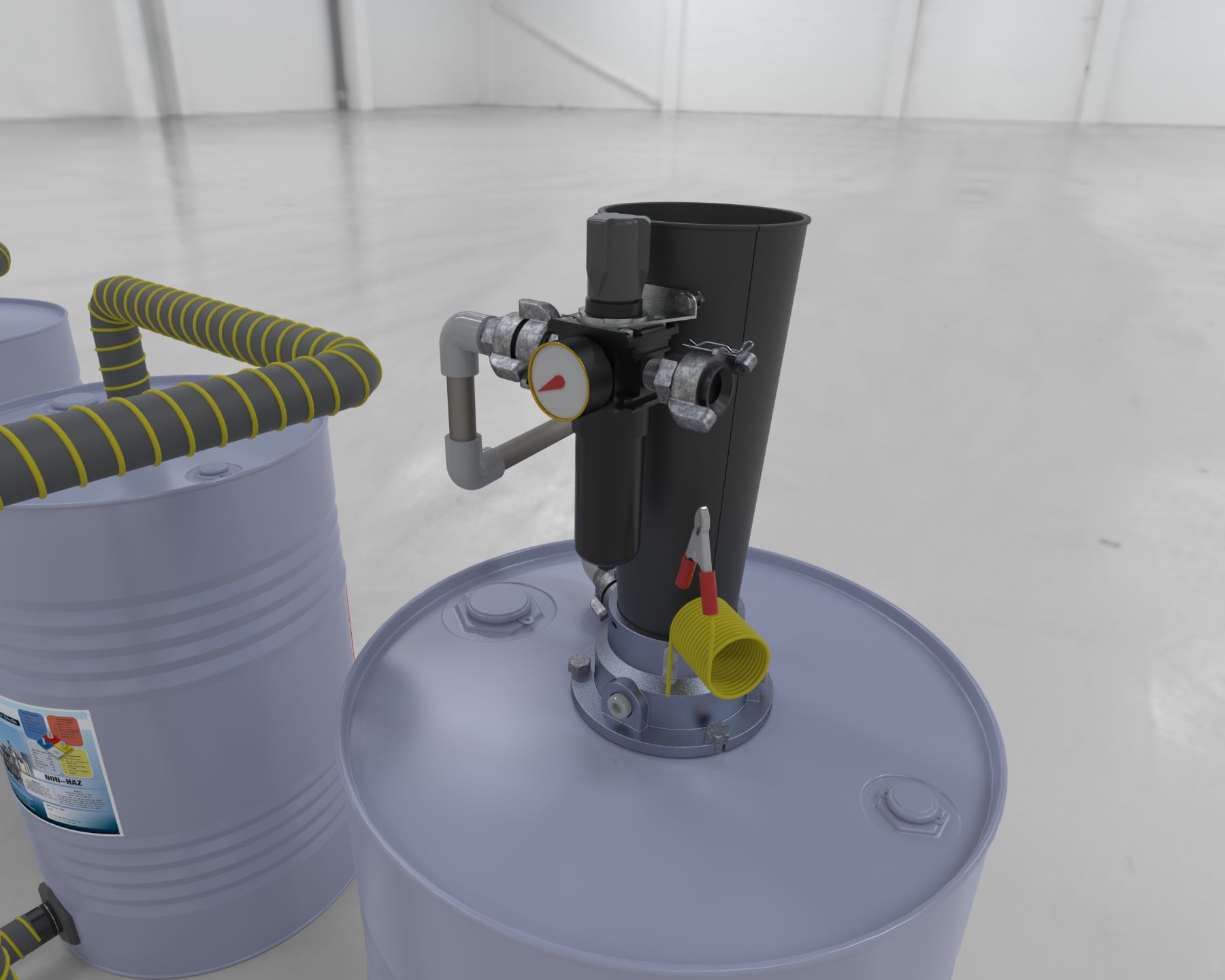

NOVAC 200 Carbon Unit

The NOVAC 200 is a direct replacement for standard 200# carbon drum adsorbers. However, this unit allows you to change out carbon within minutes yourself! The NOVAC 200 has a bottom dump valve which allows you to empty spent carbon in just 5 minutes. Furthermore, it has a temperature gauge as well as our liquid quench system which allow you to inject water into the unit if it becomes hot. Bi-directional fork slots make this unit very easy to move around as well. Holds up to 200# of regular carbon media.

HP750-VFD Blower

HP750 High Pressure Blower (VFD Controlled) is a centrifugal blower designed for 750 CFM @ 76.9" of water. Flows up to 4300 CFM (@ 10" of water) possible for applications with low pressure drop and low restriction. Great for bubble-up scrubbers and other applications with higher pressure drop. This unit is equipped with VFD to control and modulate airflow. Available for rent or sale.

HP750 Blower

HP750 High Pressure Blower is a centrifugal blower designed for 750 CFM @ 76.9" of water. Flows up to 4300 CFM (@ 10" of water) possible for applications with low pressure drop and less restriction. Great for bubble-up scrubbers and other applications with higher pressure drop. This unit has manual damper for flow modulation. VFD version available (HP750-VFD Blower). Available for rent or sale.

SSTR-54 Triple Column Scrubber

This system is made of stainless steel and mounted to a gooseneck trailer. Vapors are scrubbed through three, 54" diameter towers (8 foot tall each). Unit has on-board pump (460V) which provides flow to all three towers. Third tower has full diameter mist eliminator which removes mist particulate from exiting the scrubber. This scrubber is rated up to 6,000 CFM. Large 1800 gallon reservoir greatly enhances run times which means less down-time changing out solutions. As a separate item, a radial carbon adsorber (R4K Radial) is available to polish vapors up to 99.99%. This unit simply sits behind the scrubber system and may be connected to a blower to help evacuate tanks or process equipment.

1500 CFM Steel Blower

1500 CFM Blower with 20.5" of water (static pressure). Excellent for scrubber systems and carbon adsorption systems. Includes class 1, div 2 starter box (460V). Unit is designed for non-corrosive applications. Includes damper valve.

10,000 CFM Blower

Vapor Tech offers a 10,000 CFM centrifugal blower for rent. This unit is VFD driven . Unit is rated for 10,000 CFM @ 22" of water. VFD allows for variable CFM throughput. Available for short or long term rental.

STORM POLY BLOWERS

Vapor Tech offers STORM poly blowers for rental or for sale. These blowers are manufactured from 100% poly materials and are excellent for corrosive applications. These work great paired with poly vapor scrubbers where corrosive vapors and liquid are present. Available for weekly or monthly rentals.

Air Venturi Blowers

These units are great for applications which do not have large amounts of pressure drop. Furthermore, they are compact and when grounded offer explosion-proof (class 1, div 1) protection. These operate off of compressed air or nitrogen and do an excellent job providing suction for many types of applications. Some include general tank venting, scrubber system venting, carbon system venting, process venting, etc. These work great for drum applications (VP-55) or for larger applications.

Coppus Blowers

A step up from a venturi-blower is a coppus fan. A coppus fan uses compressed air to spin blades located in an enclosure. High flow rates are possible with a coppus blower if pressure drop is kept low. Even in you have large pressure drop these blowers will perform well and can achieve up to 30% of their maximum flow in most cases. These are mostly used for large tank venting as well as for providing adequate flow to scrubbers and carbon systems. Coppus blowers are considered TEXP (explosion-proof) and can be used in hazardous locations. 20" and 24" diameter versions available.

Eliminator 550 Scrubber System

The Eliminator 550 is a 'forced induction' vapor scrubber unit. The main shell and internals of this unit are made from 304 stainless steel for corrosion resistance and longevity. These units use the force of the vapors through the unit to come in contact with our specialized stainless distributors which are located inside of the unit. The primary distributor creates a 360 degree pattern for the vapors to radiate out to the main distributor. The main distributor has enormous surface area yet provides almost no back-pressure inside of the unit. It is here where liquid-to-vapor cohesion takes place. This transfer zone yields extremely high removal efficiencies (high as 98%) for compounds such as hydrocarbons.

Eliminator 250 Vapor Scrubber Unit

The E250 is a 'forced induction' vapor scrubber unit. This unit is a smaller version of our popular E550 vapor scrubber unit. The main shell and internals of this unit are made from 304 stainless steel for corrosion resistance and longevity. These units use the force of the vapors through the unit to come in contact with our specialized stainless distributors which are located inside of the unit. The primary distributor creates a 360 degree pattern for the vapors to radiate out to the main distributor. The main distributor has enormous surface area yet provides almost no back-pressure inside of the unit. It is here where liquid-to-vapor cohesion takes place. This transfer zone yields extremely high removal efficiencies (high as 98%) for compounds such as hydrocarbons.

Eliminator 550-N1K Scrubber System

The E550-N1K is a complete trailer-mounted vapor scrubber unit designed for vapor flows up to 500 CFM. This complete system has an Eliminator 550 vapor scrubber unit, twin 1000 pound NOVAC carbon vessels and flame arrestor. Options such as nitrogen purge system and electric blower are available. Typically these units are being used to filter vacuum truck exhaust but they do have many other other uses including being used as a VRU for tank venting. Overall efficiency of this system is over 99.99%. Trailer mounted system makes it ideal for in-plant services. Very easy to tow behind a vehicle and set in place for operation.

PPS-24 Vapor Scrubber System

The PPS-24 vapor scrubber unit is an all-poly packed-column vapor scrubber designed for corrosive applications where steel is not suitable (example: acids, chlorinated products). This unit skid mounted and is designed for flows up to 1250 CFM. Unit has main magnetic-drive re-circulation pump and backup air diaphragm pump. Solution reservoir holds up to 450 gallons. Efficiencies as high as 99.99% possible. Options such as pH Control, blowers, level control, immersion heater and more are available. Contact a sales associate for details.

PPT-24 Poly Vapor Scrubber

The PPT-24 vapor scrubber system is an all-poly unit designed for applications where steel is not suitable. This includes acids, chlorine and chlorinated vapors or chemicals. This unit is skid mounted and comes with an electric (main) and air-operated diaphragm (backup) pump. Good for vapor flows up to 1250 CFM. The PPT-24 has two towers with a total packing height of over 7'. The unit has a large solution reservoir (450 gallons) which reduces down-time to change spent chemical media. Options such as pH control and blowers are available. Available for purchase or rental.

Eliminator 450 Scrubber System

Vapor Tech's Eliminator 450 Vapor Absorber Unit is designed to treat hydrocarbon emissions from vacuum trucks and tanks. Unique 100% stainless steel design requires no utilities and offers up to 98.5% removal of organics such as gasoline in the vapor phase. This system can be placed in a 'high work' area and during vacuum operations trucks may hook their pump exhaust to the unit to meet air regulations. These are also effective for use on frac-tanks and other small tanks to handle vapors during product movements (displacement). BIO SCRUB X chemical agent has been used in this scrubber unit and has been shown to yield ultra-high removal efficiencies. This chemical media is economically priced and spent media in most case may be used as fuel due to the high BTU value. Eliminator 450 comes standard with sample ports, check valve and knock-out pot. Available for short or long term rental.

NOVAC 750 Carbon Unit

The NOVAC 750 is a continuation of our popular NOVAC series carbon adsorbers. Designed for applications within the 20-550 CFM flow range. Includes temperature gauge and water/nitrogen purge system which greatly increases the safety of the unit and limits chance of thermal event or bed fire. Unit holds approximately 750 pounds of activated carbon media. The NOVAC style units are unique in that they do not require vacuum service to unload spent media. When media is spent, simply raise unit into the air with forklift, place a carbon sack under the discharge valve, and then open the bottom discharge valve. Save valuable time and resources! Never wait for a vacuum service or cyclone again! Available for rental or purchase.

NOVAC 1000 Carbon Unit

The NOVAC 1000 is a one-of-a-kind carbon vessel. This unit holds 1,000# of GAC and is good for airflows up to 1000 CFM. What makes it unique is the fact that is does not require spent carbon removal service such as a cyclone or vacuum truck to remove spent carbon. When your carbon is spent simply lift the NOVAC 1000 with a forklift into the air, attach a fresh carbon sack to the bag hooks under the unit, and then open the bottom lever valve to allow the carbon to flow out of the unit. You can remove spent carbon and add fresh carbon back into unit within 15 minutes. Not only are these units easy to service, but they are the safest carbon beds on the market, hands down. Each NOVAC 1000 has dual temperature gauges with deep wells. These give immediate core temperature readouts and can signify if you have a thermal issue. Each unit also has an emergency liquid purge system. If temperatures do get out of hand, you can attach water to the valve located on the unit and open it to saturate the entire unit with fresh water. This will greatly help avoid a bed fire. Lastly, all NOVAC 1000 units have ladders which safely allow access to the top of the unit. Units available for rental or purchase.

NOVAC 2000 Carbon Unit

The NOVAC 2000 is a one-of-a-kind carbon vessel. This unit holds 2000# of GAC and is good for airflows up to 1500 CFM. What makes it unique is the fact that is does not require spent carbon removal service such as a cyclone or vacuum truck to remove spent carbon. When your carbon is spent simply lift the NOVAC 2000 with a forklift into the air, attach a fresh carbon sack to the bag hooks under the unit, and then open the bottom lever valve to allow the carbon to flow out of the unit. You can remove spent carbon and add fresh carbon back into unit within 15 minutes. Not only are these units easy to service, but they are the safest carbon beds on the market, hands down. Each NOVAC 2000 has dual temperature gauges with deep wells. These give immediate core temperature readouts and can signify if you have a thermal issue. Each unit also has an emergency liquid purge system. If temperatures do get out of hand, you can attach water to the valve located on the unit and open it to saturate the entire unit with fresh water. This will greatly help avoid a bed fire. Lastly, all NOVAC 2000 units have ladders which safely allow access to the top of the unit. Units available for rental or purchase.

R4K Radial Carbon Unit

Vapor Tech's R4K radial carbon bed adsorber is designed for airflow rates up to 10,000 CFM with low pressure drop (when compared to traditional linear beds). Unit holds 4000# of vapor phase carbon media. This adsorber includes Vapor Tech's one-of-a-kind safety features such as multiple temperature gauges as well as liquid/nitrogen purge system. Top easily removes for removal and loading of carbon media. Large internal manways provide easy access to internals. Main internals are 304 stainless steel. There is no other radial carbon bed on the market like this unit! Comparable systems for this flowrate are typically 8'W x 22'L and hold 10,000# of carbon. This unit is excellent for use in areas where space is limited. Large fork slots make the unit easy to move around. Available for sale or for rental.

1KR Carbon Unit

The 1KR carbon vessel is a standard vapor phase carbon vessel which holds 1000# of vapor phase carbon media. This unit is equipped with temperature gauge and a nitrogen purge inlet line. This unit also has bottom clean-out for particulate as well as a large 20" manway located on the top of the vessel. Designed for vapor flows up to 1000 CFM.

PET-48 Poly Vapor Scrubber

The PET-48 is an all-poly liquid vapor scrubber designed for airflows up to 3000 CFM. This unit is manufactured from 100% poly materials which makes it ideal for corrosive applications. Great for neutralizing vapors including acids, bases, H2S, ammonia, chlorine and many more. Removal efficiencies as high as 99.9% possible. Skid mounted for easy mobility. Available for rent or sale.

VP-55 Carbon Adsorber

Our standard, 55 gallon drum size carbon adsorber. Heavy duty (DOT rated) drums epoxy lined (internally and externally). Rated for vapor flows up to 120 c.f.m. Excellent for removal of hydrocarbon and organic vapors. Air operated venturi or electric blower available as an option. Contains approximately 200 pounds of granular activated carbon media (GAC). Carbon has the unique ability to remove many types of hazardous and odorous compounds from the air. Overall efficiency on most hydrocarbons is 99.9%+. Not for use on vapor streams that contain aldehydes or ketones as there is an elevated fire risk.

VP55A Carbon Adsorber for Ammonia

The VP55A carbon adsorber is designed for vapor phase flows up to 120 CFM. A specialized acid impregnated media (400 pounds) specifically targets ammonia and amines. Removal efficiency as high as 99.9%. Available in larger sizes as well.

VP55D Carbon Adsorber for H2S

The VP55D carbon adsorber is designed to convert H2S and other reduced sulfur compounds into elemental sulfur. This product has the remarkable ability to adsorb up to 30% by weight with H2S versus 4% with regular activated carbon. Designed for airflows up to 120 CFM. Heavy duty, DOT rated drums are epoxy lined (internal and external). Contains approximately 175 pounds of Darco H2S carbon media. Options such as air or electric blower available.

PES65-12 Vapor Scrubber

The PES65-12 model vapor scrubber is excellent for up to 125 CFM vapor throughput. This system is designed primarily for neutralizing acids, ammonia, amines, bases, and other corrosive materials. Units come equipped with sealless magnetic drive electric pumps which provide dependable, long-term use. These units can be equipped with blowers, containment, pH metering, pH control, immersion heaters, and more. In fact, all of our systems are custom manufactured around your specifications. Contact Vapor Tech for more details.

PES30-18 Micro Scrubber

Small, ultra-compact poly liquid vapor scrubber designed for corrosive applications. Great for acids, ammonia, chlorine and other corrosive products. Excellent for use for small tank venting, reactor emissions or other small vapor control applications. Unit has 30 gallon solution capacity and 18" column with over 3 feet of packing height. System comes with magnetic-drive sealless pump and has many options available such as pH control system, blower, and level control. Unit is skid mounted for easy mobility or could be moved around with a dolly.

PES225-18 Scrubber

This particular unit is designed for more moderate flows (up to 500 cfm). 100% Poly construction. Unit shown has 225 gallon reservoir with a 18" x 72" tower. This custom unit is equipped with a 100% poly magnetic-drive re-circulation pump. Many other options such as poly blower, pH control system, immersion heater available. Contact us today for more details. Custom units available!

Eliminator E550-1000 Scrubber System

The E550-1000 is a skid mounted vapor control system comprised of a forced induction vapor scrubber followed by twin 1000# carbon beds. Designed for vapor flows up to 500 CFM. This system has a stainless steel E550 which alone can achieve 98% removal of vapor contaminants such as hydrocarbons. The twin 1000# carbon beds polish the vapors to near 100% removal. This system has temperature gauges and emergency water quench system which make it the safest system available today. Large carbon extraction valves make removal of spent carbon possible within 15-20 minutes. No carbon extraction machine or cyclone required! Catwalks included for both carbon bed which makes loading of fresh carbon safe and easy.

E6500-R3K High Volume Scrubber

Trailer mounted wet scrubber followed by twin 3000# Radial Carbon Beds. Designed for flows up to 6500 CFM with low pressure drop. Excellent for tank venting, hydroexcavation vapor control, airmover exhaust, GAP Vac exhaust and many other applications.

Eliminator 5500 Scrubber System

The Eliminator 5500 scrubber unit is designed to treat hydrocarbon and other vapors from Air-Movers and GapVac units which typically have exhaust streams around 5500 CFM. This system has large solution capacity (minimum of 1375 gallons) and requires no utilities to operate. High efficiencies for hydrocarbons and other emissions are possible (98%+) due to the unique distribution system inside the unit as well as the proprietary mist elimination system. These units require roll-off truck service for delivery and pickup and are available for weekly and monthly rentals. For hydrocarbons we highly recommend our BIO-SCRUB X chemical media which has been shown to remove 98.5% of VOC's (gasoline) in this type of system. Spent media in most cases can be reused for fuel or stripped and reused.

VTS36-500 Vapor Scrubber System

The VTS36-500 is designed for vacuum truck emissions. This system mounts directly behind the cab of a stretched vacuum truck or it can be mounted to a trailer and towed around to where it is needed. This system is comprised of a high efficiency liquid vapor scrubber unit (forced-induction) followed by twin, 500# carbon beds. Scrubber alone is capable of 98.5% removal of hydrocarbon vapors (using Bio-Scrub X chemical media). Dual carbon beds following scrubber polish total vapor stream to 99%+ in most cases. This system includes vapor monitoring points between each component which enables the operator to accurately pinpoint when chemical and/or carbon is becoming spent. In addition, this unit has safety features unlike any other system on the market. Each carbon bed has dual tempererature gauges for instant core temperature feedback. In addition, the unit is equipped with a water-purge system which when activated, floods each carbon vessel with water to help avoid a fire or unsafe elavate temperature event. The chemical and carbon medias are very easy to load and unload. This unit does not require carbon extraction services. Each bed has a large valve which when opened will allow carbon to flow out of the vessel. Cleanouts below each vessel allow for cleaning of 'fines' and debris which accumulate below the grids. This system is very versatile and allows the vacuum truck to scrub many types of different vapors. It is merely a function of the chemical media (and carbon in some cases) used in the system. Contact Vapor Technologies, Inc. for help determining which chemical is right for your application.

CSS-18 Vapor Scrubber System

The CSS-18 vapor scrubber is ideal for applications which require a small footprint as well as low pressure drop. These units are available with air pneumatic pump or electric pump. 50 gallon solution reservoir is ideal for small tank applications. High quality powder-coating finishes off the unit. Excellent for Frac-Tank emissions during breathing or filling operations. Stainless Steel version available.